Cnc Beam Drill Line Quantum

Importing files directly into your steel detailing software is a better option. It eliminates unnecessary steps and can also prevent any incorrect data capture. This is a distinction that can be distinguished into two camps:

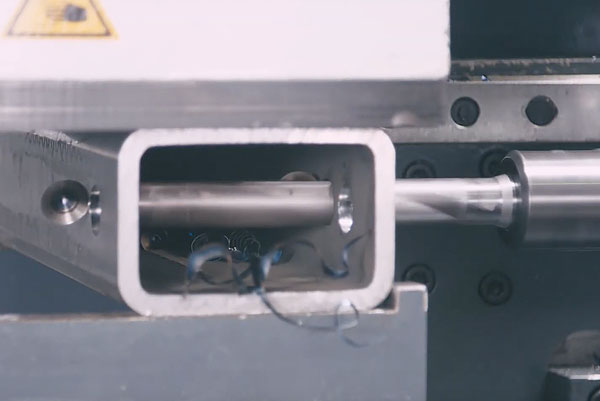

The CNC Beam Drill Line can lay out and drill all of your holes in any type of steel profile in fractions of the time that it takes to do manually with a mag drill. It also marks all your welded attachments, eliminating the need to use a tape measure.